Introduction to

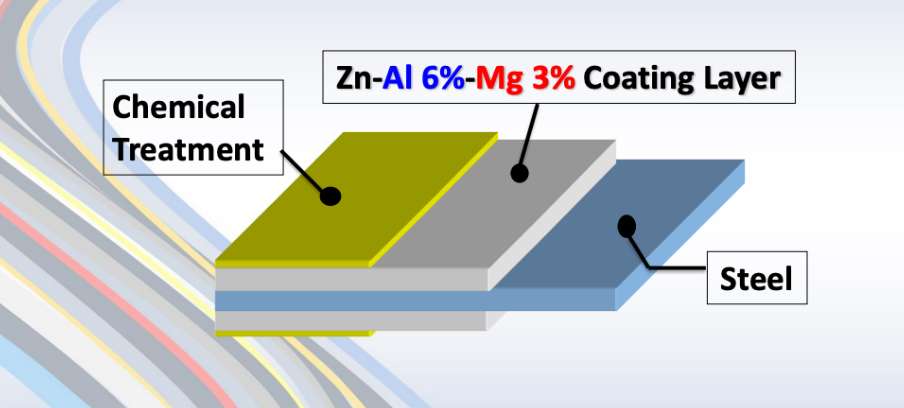

WHEELING-NIPPON STEEL is proud to announce our newest product, ZAM® - branded the "Corrosion Protection of the 21st Century". ZAM® is a remarkably superior corrosion-resistant hot-dip Zinc-Aluminum-Magnesium alloy-coated steel sheet product, with the best corrosion protection for steel currently available on the market. WHEELING-NIPPON STEEL is the first and only company in the Americas to produce such a product, providing unparalleled corrosion resistance, including cut-edge corrosion resistance, making it a great choice of material in applications where corrosion must absolutely be avoided.

This amazing product is protected by a proprietary alloy, a magnesium-zinc-aluminum coating that lasts longer in the most severe environments, provides built-in cut-edge rust protection, and promotes cost savings through less maintenance, making it a fantastic choice for weatherproof roofing, especially coastal roofing.

ZAM® uniquely presents a self-healing, ecologically friendly alternative to other conventional metal coatings. Besides the key features listed at right, ZAM® exhibits exceptional alkaline resistance - even in direct contact with concrete and mortar.

ZAM® is a great substitute avoiding the need to use more costly stainless steel, aluminum and post-dip batch coated steel products. Parts requiring these materials are ideal candidates to convert to cost-saving ZAM® coated sheets.

ZAM® is produced to ASTM A1046/A1046M Type 1 specifications and is utilized where the absolute best rust prevention and cut edge protection are needed.

Got Rust? Get ZAM®. You too will be convinced that ZAM® is like no other corrosion-resistant coated sheet product. Please explore the many technical and comparison studies located on this site under the tabs "About ZAM®", "Technical", and "Applications".

Key Features of ZAM® Coated Steel Sheet

- ZAM® creates cost savings through longer service life and reduced maintenance

- ZAM® eliminates the need for post dip (batch) galvanizing

- ZAM® bridges the product gap between heavily coated galvanized and costly stainless steel

- ZAM® offers a thinner coating yet more protection. Environmentally friendly, less zinc run off

- ZAM® is excellent in severe environments - especially coastal and agricultural

- ZAM® offers cut edge corrosion protection - the hallmark feature of ZAM®

- ZAM® offers superior formability due to coating characteristics

ZAM® Specifications

| 0.014" through 0.130" | ||||||||||

| Material Width | 24" through 61" | |||||||||

| ASTM A1046/A1046M Type 1 | ||||||||||

| Steel Grades |

|

|||||||||

| Coating Weight |

|

|||||||||

| Coil Weight | 10,000 lbs. minimum through 55,000 lbs. maximum | |||||||||

| Coil ID | 20" and 24" | |||||||||

(upon request) |

|

ZAM® Applications

Suitable applications for ZAM® include: construction (architectural building panels, roofing, perforated panels, board and batten panels, metal facades), automotive (motor housings, ECU covers, LCMs, brackets), agricultural applications (animal structures, hoop buildings, grain bins, silos, farm and implements, green house structures), industrial HVAC, cooling towers, solar racking, school bus platforms, swimming pool walls, sign posts, guardrail facades, coastal environments, cable trays, switch boxes, steel decking and framing, sound/wind/snow barriers and many other applications.

Prepainting and color coating ZAM® is regularly done with very good results and reviews. WHEELING-NIPPON STEEL recommends working with your paint supplier to choose the best paint system for your application.

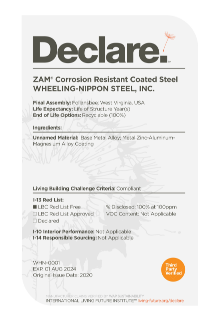

ZAM® Earns Declare Label

Product designers and architects demand sustainable flat rolled corrosion-resistant steel that is friendly to the environment and is healthy, by design, to those that use their products. ZAM®, proudly Made in the USA by Wheeling-Nippon Steel, offers superior corrosion performance, is 100% recyclable and when utilized properly will last the designed life of the structure. ZAM® is Eco-Friendly using less of the earth's resources and outperforms other corrosion-resistant flat rolled steels in the most demanding applications.

We are proud that ZAM® earned the Declare label and is included in the product database of the International Living Future Institute.

ZAM® Warranty

- Due to ZAM®'s degree of corrosion resistance, WHEELING-NIPPON STEEL offers a long-term warranty for ZAM® Steel Sheeting.

- Contact your WHEELING-NIPPON STEEL sales representative for further details. For new inquiries, click the following link for ZAM® Contact Information

ZAM® is ASTM Specified

- ZAM® is produced to ASTM A1046/A1046M Type 1 (Standard Specification for Steel Sheet, Zinc-Aluminum-Magnesium Alloy-Coated by the Hot-Dip Process) specifications.

- ZAM® is specified for use as cold formed steel framing in ASTM A1003 (Standard Specification for Steel Sheet, Carbon, Metallic-Coated for Cold-Formed Framing Members).

Additional ZAM® Resources

Frequently Asked Questions on ZAM® Coated Steel Sheets

What is ZAM® coated steel, and how is it different from traditional galvanized steel?

ZAM® coated steel is a highly durable steel product coated with a blend of zinc, aluminum, and magnesium. This unique coating enhances corrosion resistance, surpassing traditional galvanized steel's performance by offering extended life and better protection in harsh environments.

What applications are best suited for ZAM® coated steel?

ZAM® coated steel is ideal for various applications, including construction, automotive, agriculture, HVAC systems, and solar panel frames. Its superior durability and corrosion resistance make it perfect for environments exposed to moisture, chemicals, or extreme weather.

How does the corrosion resistance of ZAM® coated steel compare to other coatings like Galvanized Steel or Galvalume®?

ZAM® coated steel provides significantly better corrosion resistance than conventional galvanized and Galvalume® coatings, especially in terms of durability and adhesion in cut-edge or perforated-edge applications. The magnesium content in the coating enhances self-healing properties, offering long-lasting protection even in more demanding environments.

Is ZAM® coated steel environmentally friendly?

Yes, ZAM® coated steel is designed with sustainability in mind. Its extended lifespan reduces the need for frequent replacement, and the coating process minimizes waste while maintaining high recyclability. Learn more about ZAM®'s environmental impact.

Can ZAM® coated steel be fabricated and welded like traditional steel products?

Absolutely! ZAM® coated steel is easy to fabricate, cut, and weld using standard equipment. Its coating is engineered to maintain performance and adhesion even after processing, ensuring durability and functionality in the final product.

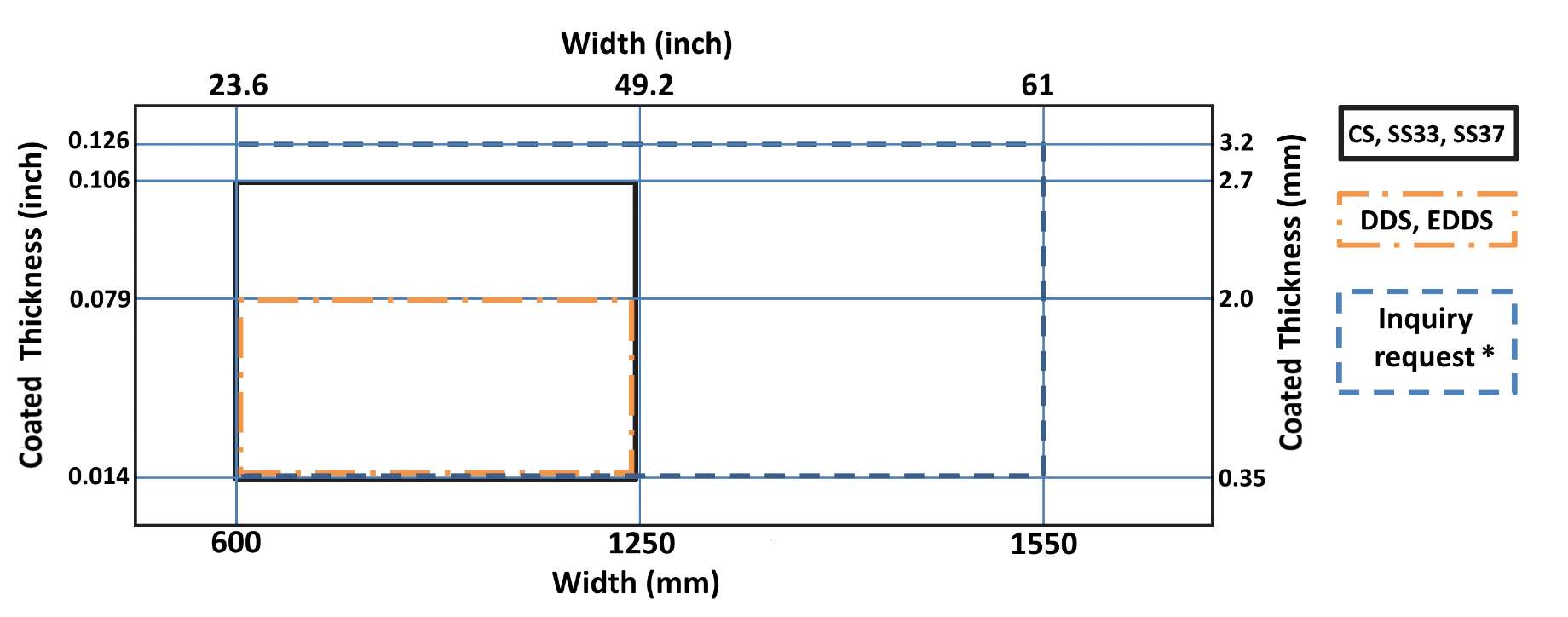

ZAM® Specification Diagrams

Available Sizes

* Please contact your WHEELING-NIPPON STEEL sales representative or for new inquiries, one of our ZAM® Contacts

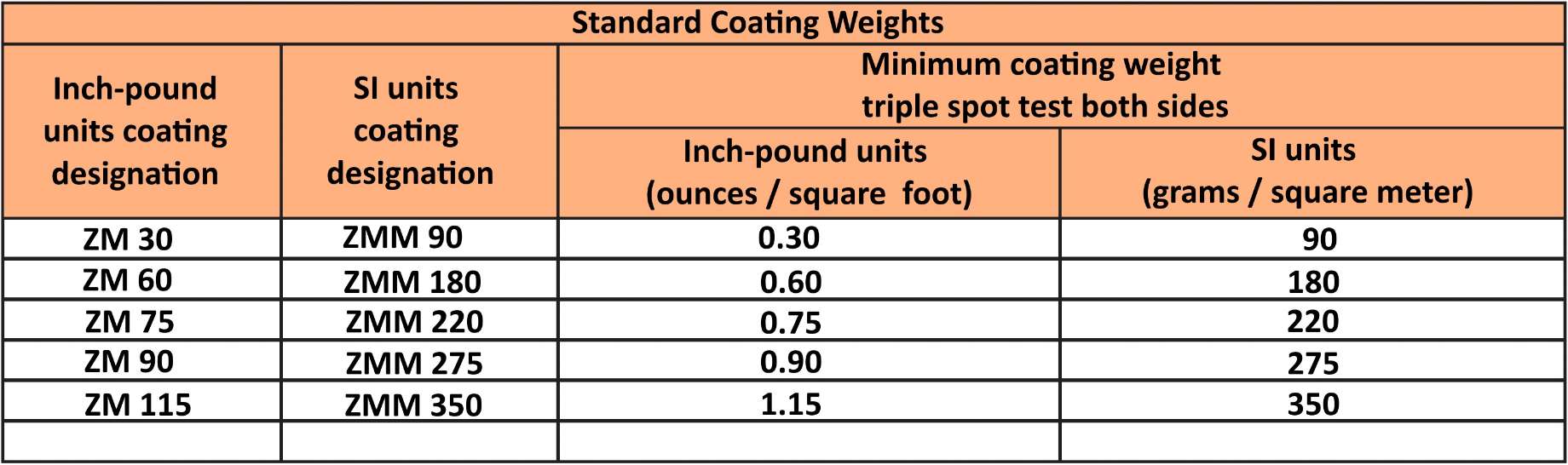

Coating Weights

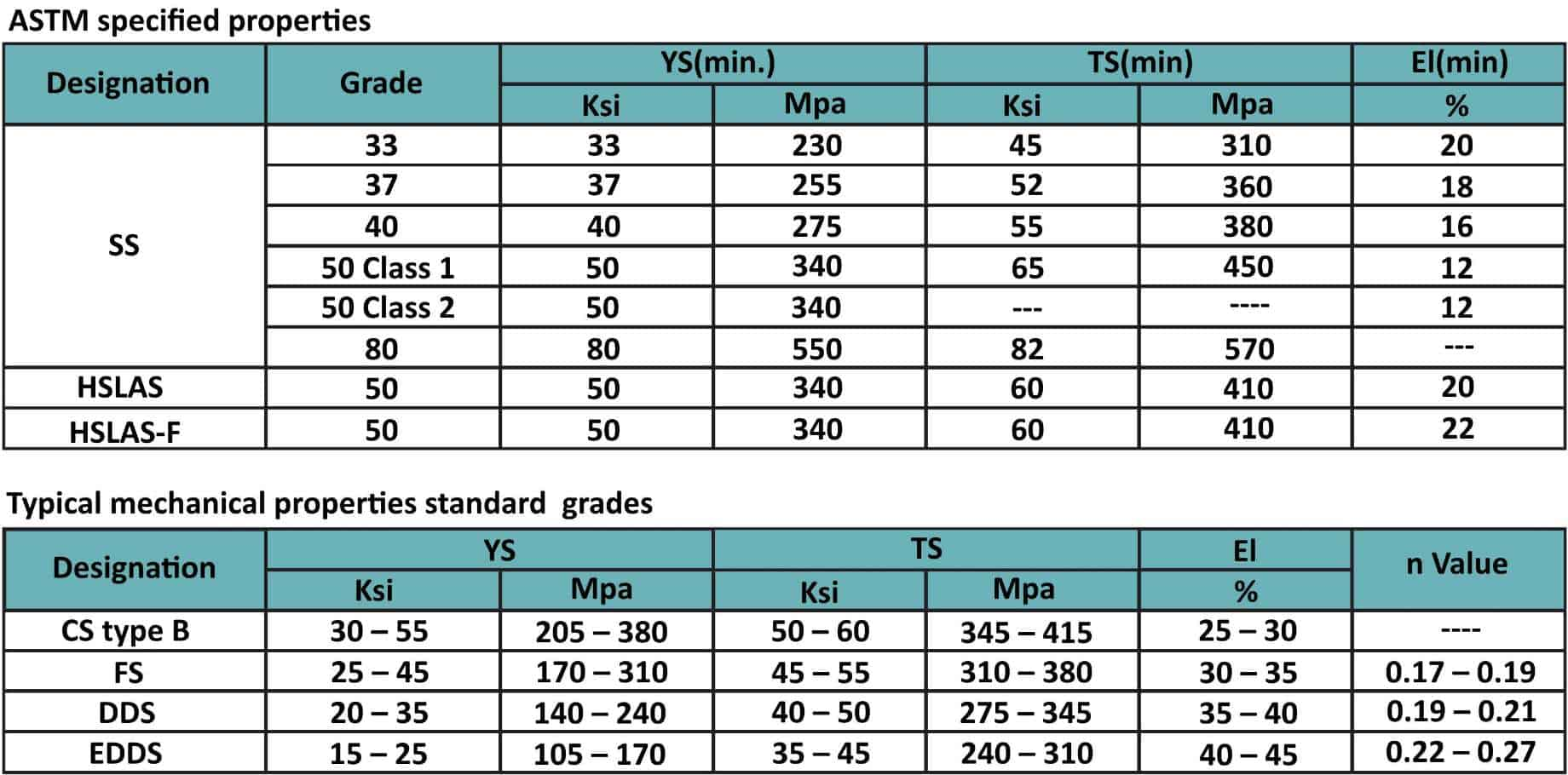

Steel Grades

PO Box 635

Follansbee, WV 26037

Phone: (304) 527-2800

Fax: (304) 527-0985

GET IN TOUCH