ZAM® is Very Durable

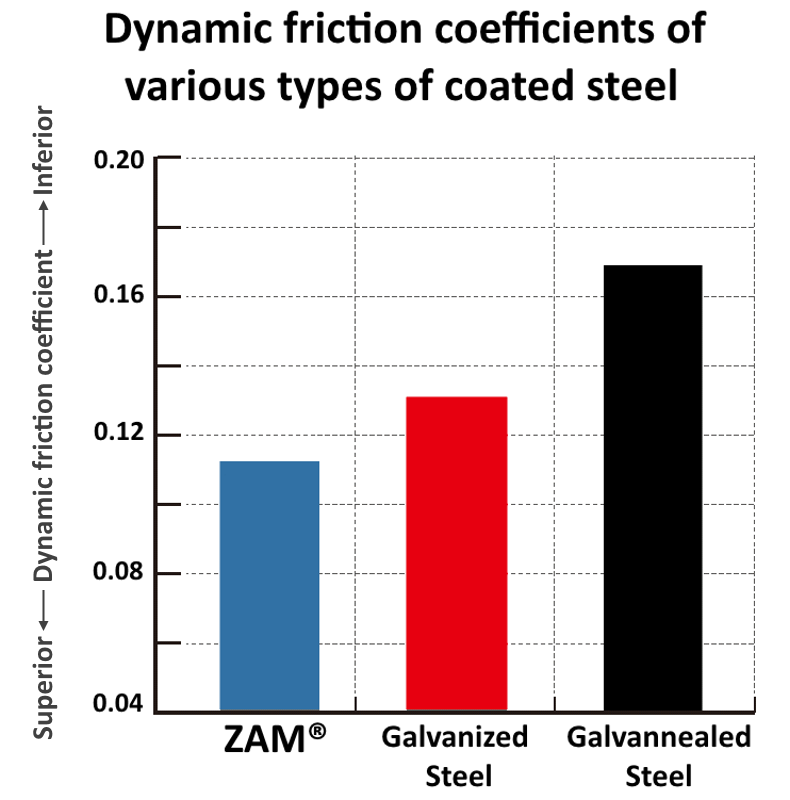

Dynamic Friction Coefficient

ZAM® exhibits superior sliding characteristics since its coating has a high surface hardness and smoothness. This is also beneficial in that coating will not build up as readily on tooling, thus reducing down time for maintenance clean up, leading to higher productivity.

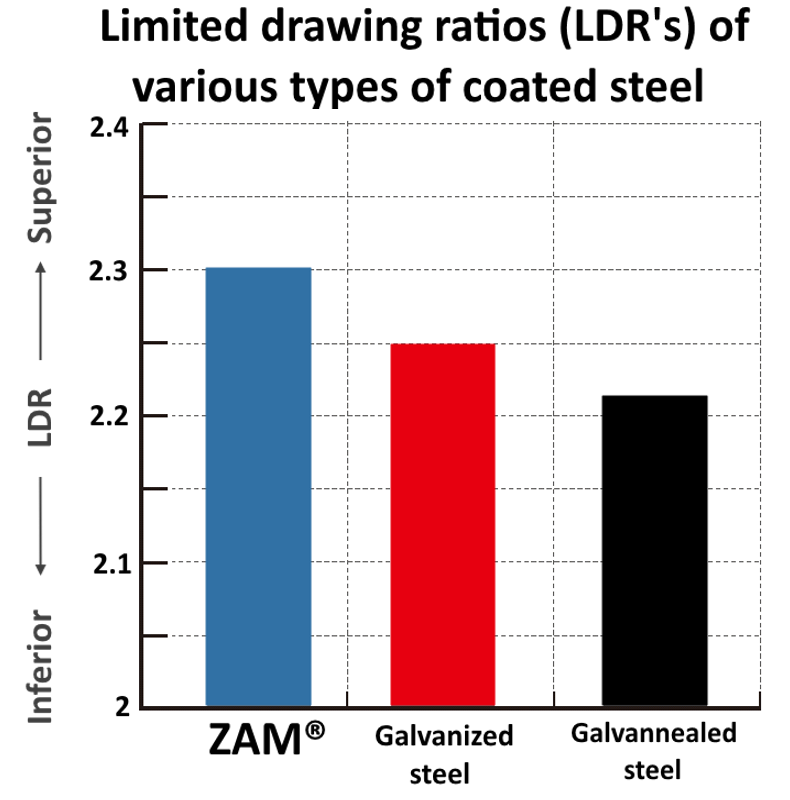

Limited Drawing Ratio

ZAM® has better drawing characteristics than other types of coated steel sheets due to its smoother and harder coating.

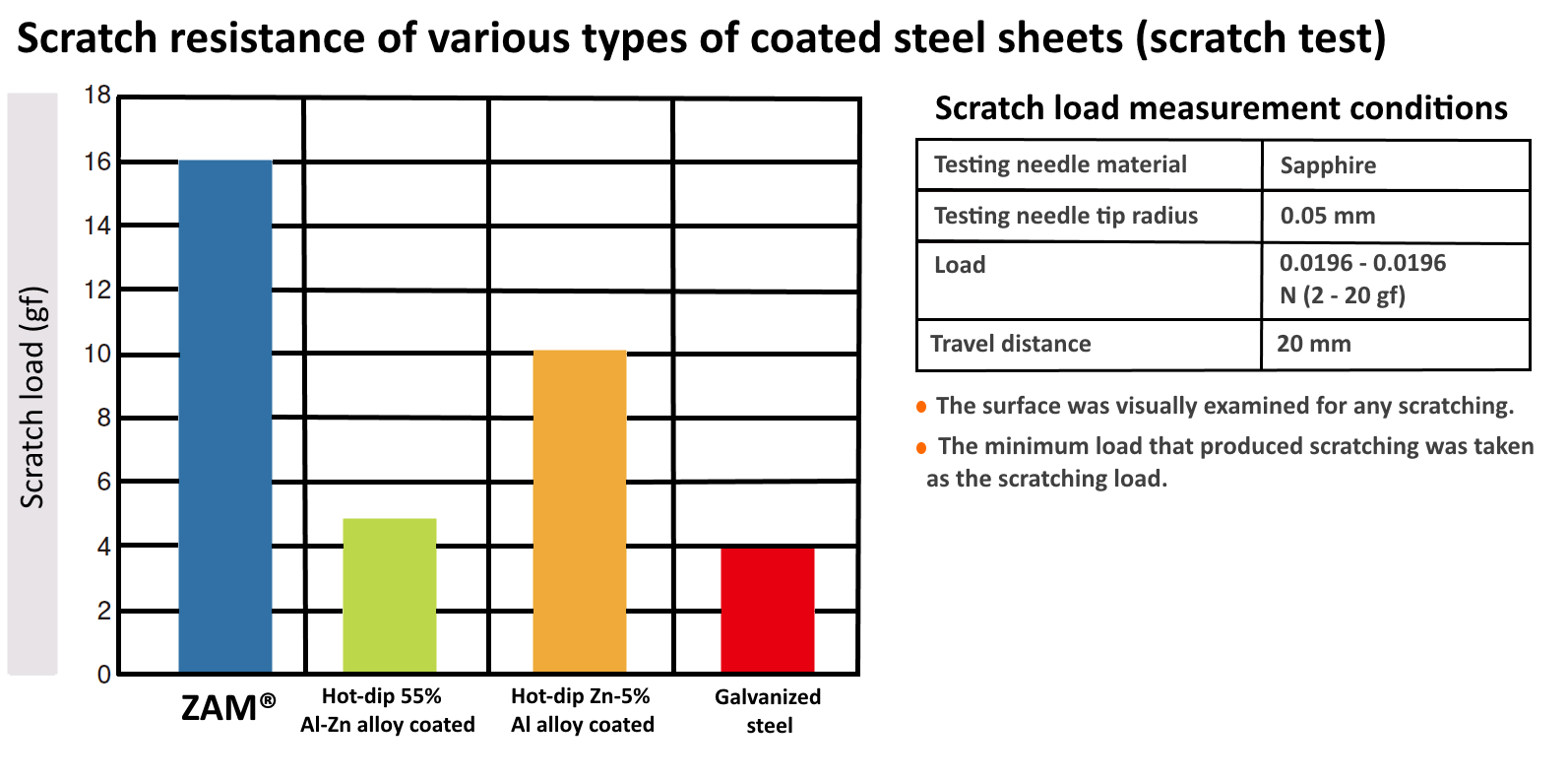

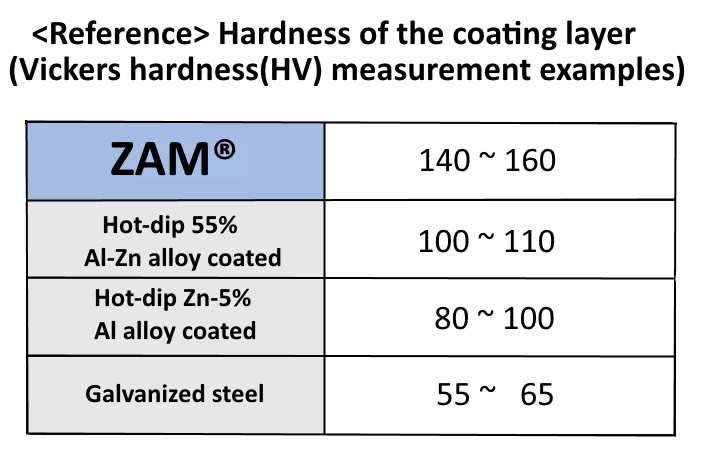

Better Scratch Resistance

Zn, Al and Mg Alloy coatings have a harder coating layer than hot-dipped galvanized or aluminum-zinc alloy coated steel sheets. Thus, offering better scratch resistance and can be used in applications where it is subjected to scratching and repeating friction during processing.

Eco-friendly

Eco-friendly